Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide

Maintenance work order cost tracking can be a challenge. For instance you run a large equipment maintenance program and create several hundred work orders a month. How well are you alerted to material and labor usage problems?

Maintenance work order cost tracking can be a challenge. For instance you run a large equipment maintenance program and create several hundred work orders a month. How well are you alerted to material and labor usage problems?

Not being able to track such items will often result in unexpected costs that will break your budget. In addition, keeping an eye out for overruns can alert you to possible issues. For example you estimate an equipment maintenance task should take sixty minutes. However, the work order actually took ninety minutes to do. The technician made mistakes due to lack of training or experience.

Have you ever had this happen to you?

Using maintenance software to track work order cost

Maintenance management (aka CMMS) software can help you track actual maintenance work order cost and labor hours spent vs. estimates. How does this work?

You create a “library” of standard maintenance tasks that detail how each job should be done. Then use these tasks as templates to create work orders. The costs and labor hours entered on the maintenance task template are your estimates of how long the work order would take to complete. These values are copied onto work orders created from the task as the default values.

Say the cost & the time taken to complete the work order are different. Update this on the work order. You can use this information to make useful work order reports. Compare the estimated duration of a work order to the actual duration to identify possible issues.

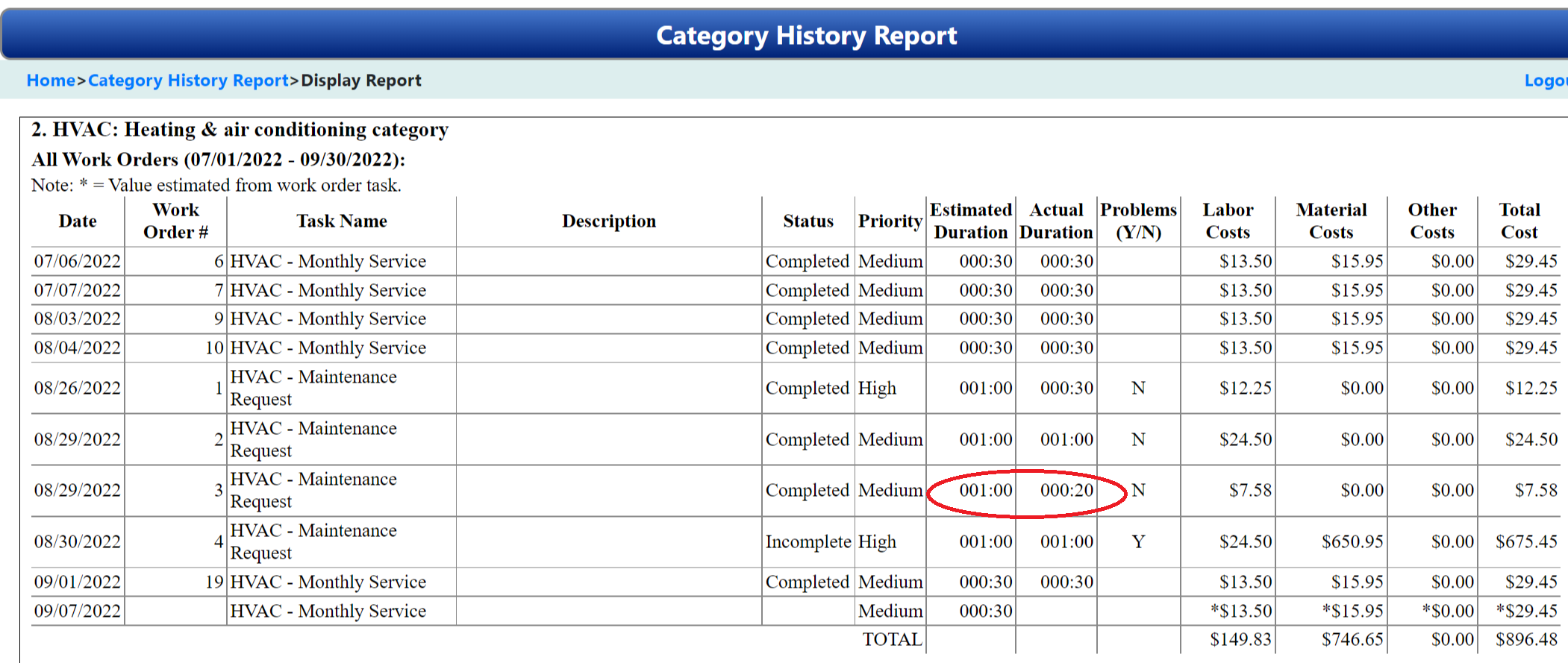

For instance below we have a sample Category History Report showing work orders with their estimated duration as well as actual duration. On 8/29/2022 we see a work order that was estimated to be completed in 60 minutes but was done in 20 minutes. While this is not an overrun it is still a good idea to open up the work order to check why the actual time took less than estimated.

Over estimation of costs and labor can also cause you to pre-allocate most of your budget. This will leave you with too little for other priority and lower urgency items. For example, training, hiring additional personnel, tool replacement and more.

Tips to find the best maintenance software for your needs

With hundreds of programs available it can be hard to find the perfect fit. Use this free guide to find the best maintenance management program for your needs.

Free CMMS Software Selection GuideEssential Maintenance Metrics Every Planner Needs to Know

Get Free Guide