Essential Maintenance Metrics Every Planner Needs to Know

Get Free Guide

Maintenance managers are acutely aware of how CMMS software aka maintenance software can improve maintenance operations and reduce expenses. However, it can be difficult to get support from senior management or business owners to buy such software and put it to use.

Have you ever had this happen to you?

On the other hand…

From management’s point of view, there are several other areas besides maintenance software where such capital expenditures can be made. Nearly all of these can also improve business operations.

So how do we justify putting limited budget dollars to get maintenance software versus spending it elsewhere?

Maintenance Software Impacts On Business Decisions

Maintenance is one of those unheralded operational areas. Often ignored when there is no major crisis!

However, there are a number of reports and features available in CMMS software. They can be helpful to senior management and business owners to cut costs and improve profitability. Use them to present your case and get a budget for a CMMS software program.

We will look at some of these using FastMaint CMMS as an example. Similar reports and features exist in other maintenance software.

Many types of business can use maintenance software. For instance, we can consider two different business types. Firstly a small to mid-size manufacturing operation. Secondly a small to medium sized commercial facility that provides services to different customers. This could be something like a hotel or resort, an office complex, a restaurant and so on. However, it could just as well be applicable to other operations that have a lot of equipment or facilities. For example utility operators, refiners and so on.

1. Statistics Report

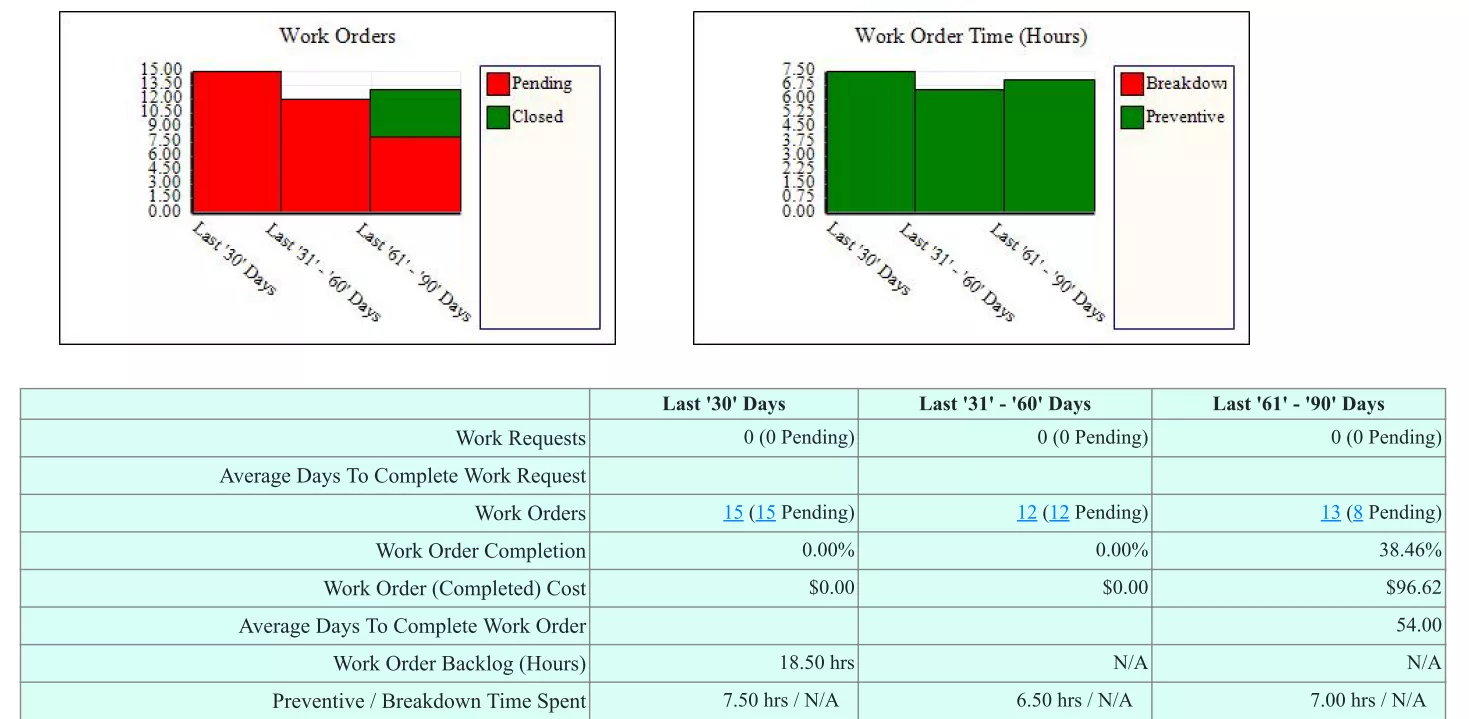

One of the most useful reports is the Statistics report in FastMaint CMMS. It has been specially designed to be shared with senior management or business owners. They do not need to have access to FastMaint. The maintenance manager can print it out and give it to them. It contains no complex and difficult to understand statistics.

The report shows performance in a current period (Last 30 Days) versus performance in two prior and similar periods. This makes it easier to catch possible issues or trends. Some items to look for are:

a) Pending work orders from prior periods

We should see if an unusual number of work orders created in prior periods are still pending. If any of these are for important assets (equipment or locations) there is cause for concern. Incomplete maintenance on an asset can mean poor product quality or service or even loss of revenue if product or service cannot be delivered.

b) Preventive vs. breakdown time spent

This ratio is expressed as a percentage. A low percentage means that most maintenance is of the breakdown type. This is expensive since it means that an asset (an equipment or location) is unexpectedly out of service. In a manufacturing operation we probably have lost production or product quality. In a commercial facility we may have upset customers or have lost revenue because we cannot rent the facility (for instance hotel rooms) to customers.

c) Equipment with most breakdown work order time

Even if the Preventive vs. Breakdown Time Spent ratio looks good, check and see if the same equipment keeps cropping up as having the most breakdown work orders. We must make sure that it is not a critical asset whose lack of availability will hinder delivery of product or service. If it is a critical asset, we may need to talk to maintenance and operations managers to see if it is time to replace it or do a complete rebuild.

Have a look at “3 Quick Maintenance Metrics For Maintenance Planners” for a more in-depth look.

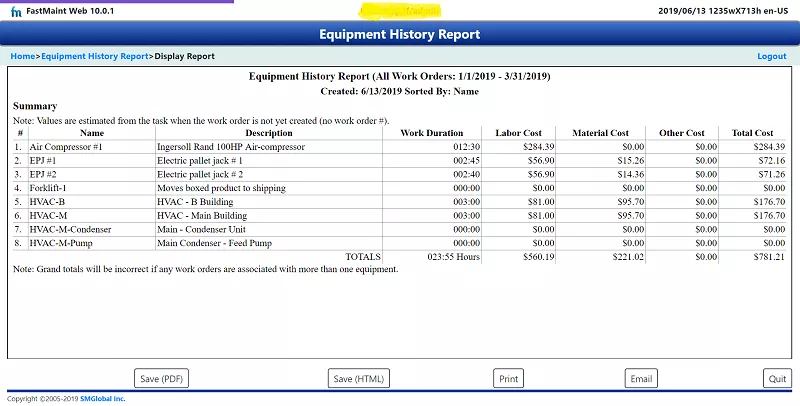

2. Work Order Analysis Report

This is another report that we can print and give to management. We want it to use the Cost & Duration Variance report template showing aggregates by Month. This report shows you how the costs and durations of different classes of work orders have varied from estimates.

If we see large unexplained variances it typically means there is a problem with maintenance and operations. We need to dig in deeper and find the underlying causes.

It could be maintenance and operations are not working well together. Or maybe some assets may have reached the end of their lives and require more maintenance than planned. Both these issues besides increasing maintenance costs will probably result in revenue and customer loss due to delays delivering products or services.

3. Equipment Maintenance Calendar

This is not a report that executive management usually needs to see. However, it has important implications for co-operation between maintenance and operations staff.

It shows when equipment is expected to be unavailable because of planned preventive maintenance. Timing is everything since equipment or facilities being unavailable during a peak period will be unacceptable.

We want to ensure that information in this report is shared between departments and adjustments are made to maintenance schedules as needed.

4. Asset Register & Asset Replacement

Most industrial plants and commercial facilities have quite a few equipment and other assets which have been purchased over several years. Frequently there is no centralized list of such assets and their costs. This is where an asset maintenance program for these facilities & equipment can really help.

We can use FastMaint CMMS to maintain a list of such assets and also track ongoing maintenance costs incurred on them.

Purchasing equipment is normally a significant capital outlay. We will offsetting these costs by making provisions for depreciation based on expected equipment life.

What happens if the equipment needs to be replaced earlier than expected due to missed maintenance? On the converse side what are the benefits we can expect if say the equipment lasts 10% longer on average because of better maintenance practices made possible with support from the CMMS software?

These sorts of items will impact our balance sheet and profit & loss statements.

In addition you can get an idea of potential cost savings & benefits from the “CMMS Benefits & CMMS ROI Calculator“.

Maintenance Software Selection Guide

If you are considering maintenance management software and are not sure where to start, this free CMMS Software Selection Guide will be quite useful. With a variety of questions and checklists it can help you identify the right product for your organization. Or you can pass along the PDF guide to others who may be responsible for the selection process.

Free CMMS Software Selection GuideEssential Maintenance Metrics Every Planner Needs to Know

Get Free Guide