Why create an equipment hierarchy?

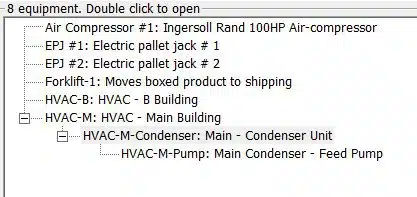

A hierarchy makes it easy to get a “tree view” of equipment. The tree shows the parent equipment and all its sub-equipment.

This tree can be used to quickly find a specific equipment that needs some maintenance. For example find a specific pump as part of an air-conditioning plant when you have several pumps of the same type.

You can also create roll-up reports to get maintenance costs and work done on an equipment including all its sub-equipment.

How to make an equipment as a sub-equipment of another

Use the “Part Of” field to specify that one equipment is part of another. For instance a pump as part of a chiller.

The parent equipment itself could be part of another equipment. This effectively creates a hierarchy of equipment. For example the chiller itself as part of an air conditioning plant.

Also create location hierarchies

Similarly you can create a hierarchy of locations. Use the “Part Of” field to specify that one location is part of another.

For example a room within a building, a work station as part of an assembly line and so on. It could even be a site as the parent location with different buildings as sub-locations and maybe floors or blocks as sub-locations within these buildings.

Each of these locations could have equipment associated with it. For instance a boiler, a room air-conditioner, a drill at a specific work station and so on.

Get total costs & work done for a location and sub-locations

You can get a roll-up of costs and work done in the location hierarchy (including any equipment in each location).

Use the Location History Report (see Locations under the Reports menu on the main window or Home page). Keep the check box “Include history of equipment in location” checked to also get details of work orders done on equipment in the location.