What are parts?

Parts are items required to complete a maintenance task. For instance an air conditioning filter, a replacement bearing, or a quart of oil. These maintenance parts & supplies form your maintenance inventory that you keep on hand to do maintenance jobs as needed.

Why is maintenance inventory management important?

Experts estimate that organizations can save between 5-10% on their yearly maintenance parts inventory costs with a CMMS software program. If you have a lot of expensive parts & supplies, the parts costs aka work order material costs can easily dwarf all other costs in your maintenance program. Proper use of CMMS software inventory management features & reports can help reduce inventory carrying costs as well work order completion time.

- Parts can be ordered in advance rather than being stockpiled.

- Parts that are no longer needed due to equipment retirements can be easily identified.

- There will be less work completion delays due to parts being out of stock when needed.

FastMaint can track inventory usage & costs

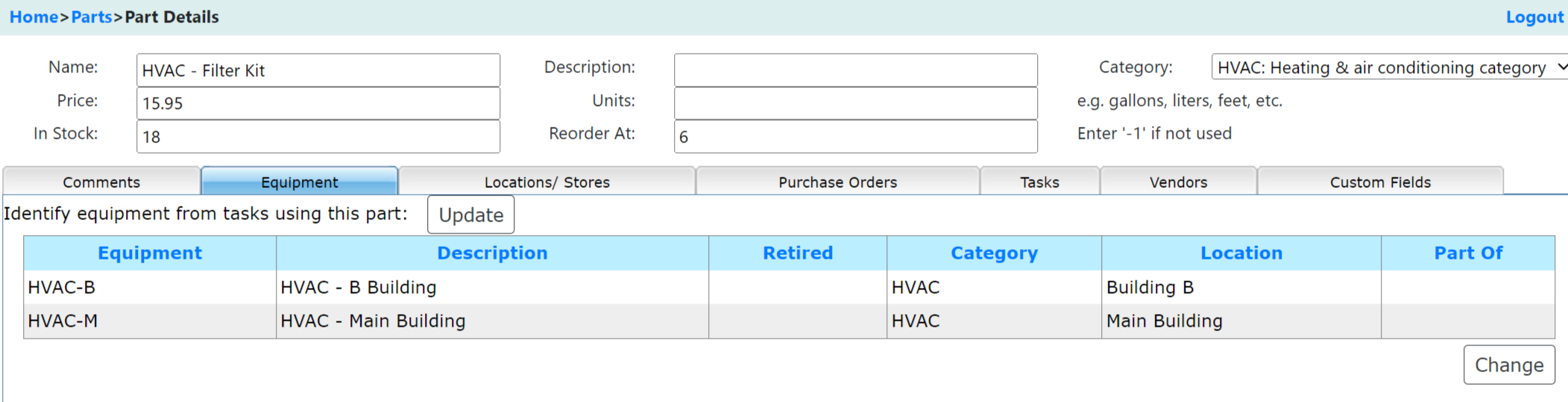

Parts & supplies needed can be specified on task templates. These will be copied onto work orders when created from the task. You can adjust parts used on the created work orders. When task work orders are done, FastMaint reduces the quantity of required parts in inventory accordingly. You can use the “Reorder At” setting on a part to identify when parts need to be reordered.

Tip: You can use the import feature to add parts to the system or update existing data for different parts such as the part prices, available quantities and so on.

Custom user defined fields for parts:

You may have additional information you want to store for each part. For instance a manufacturer’s part number, cost center codes and so on. You can add such fields under Administration> Custom Fields> Parts.

Part re-ordering & purchasing:

Purchase orders can be created to order parts from vendors. You can see outstanding purchase orders on each part. When purchase order items are received they are added to stock.

You can enter Vendors into the system and list and rate them as possible suppliers for parts. You can then generate purchase orders, and print vendor contact information on parts to reorder reports.

Associate maintenance part inventory with equipment & locations:

Parts can be associated with equipment. This makes it easier to identify what parts can be disposed of when equipment is retired. You can also use the “Equipment Details” report (Reports> Equipment> Details) to see parts associated with different equipment.

Locations can be associated with specific parts if those locations will be used as stores. You can also use the “Location Details” report (Reports> Locations> Details) to see parts associated with different locations.

Work order part management

How Material Cost (cost of parts needed) of a work order is calculated:

Depending on the settings in the task used to create the work order (in the Costs tab on the task), these are usually calculated automatically for you based on the contents of the Parts tab in the work order.

How part quantity in stock is adjusted:

If the work order status is changed to “Started” “Incomplete” or “Completed“, the quantity in stock for all parts needed for this work order will be appropriately reduced.

If the work order status is changed from “Started“, “Incomplete” or “Completed” to “Planned” or “Planned (Requested)“, the quantity in stock for all parts used for this work order will be increased since the parts will not yet have been used.

Parts history report

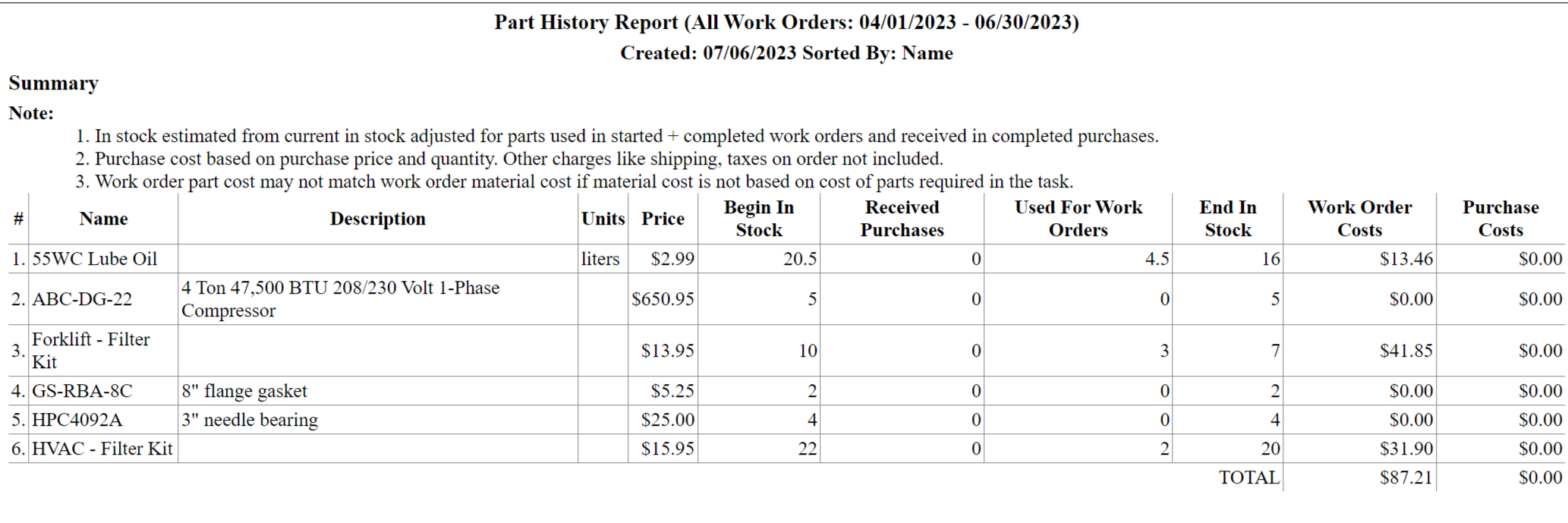

This reports allows you to compare work order parts usage costs and durations by part as well as purchased parts received, over a specified period. It is available under Reports> Parts> History.

Select the “Tabular Data” report template to get a beginning inventory (Begin In Stock) & ending inventory (End In Stock) report for the period.

Use the other report templates to get parts costs & usage graphs and more. In addition you can customize existing report templates to add custom fields or other information.