FastMaint CMMS for Equipment Maintenance

Fast to setup. Easy to Use. Cloud (pay monthly) or Download (pay one-time)

Trusted by Businesses of All Sizes - Join Our Happy Customers

Try FastMaint CMMS Today and Revolutionize Your Maintenance Management!

Here’s What You’ll Gain:

1️⃣ Lightning-Fast Setup: Import your existing data and get started in no time—no costly training or consultants required!

2️⃣ Slash Downtime with Breakdown Maintenance: Quickly handle maintenance requests to minimize lost productivity, reduce complaints, and get your team back on track.

3️⃣ Smart Preventive Maintenance: Streamline scheduling and tracking with customizable templates for routine tasks—say goodbye to tedious data entry!

4️⃣ Seamless Work Requests: Let co-workers and customers email maintenance needs directly. Get instant alerts, track requests, and easily convert them into work orders.

5️⃣ Efficient Parts Inventory: Avoid costly delays with better inventory control. Manage stock, purchase orders, and vendors with ease.

6️⃣ Insightful Maintenance Reports: Automate and customize regular reports. Schedule them to be emailed directly to your team for better decision-making.

7️⃣ Budget-Friendly Options: Choose a plan that works for you—Cloud-based (monthly) or Download (one-time payment).

8️⃣ Risk-Free Trial: Start immediately with no credit card required. Get 5 user accounts to test and explore FastMaint CMMS together.

👉 Don’t Wait! Transform your maintenance process and boost efficiency. Try FastMaint CMMS now!

FastMaint - Something Your Maintenance Team Will Actually Use!

One of the easiest CMMS programs to setup and use. The ability to add photos and drawings to parts and equipment in FastMaint is a blessing. This is often a option in other CMMS packages. Reports, Work Orders and Purchase Orders are very professional in appearance and functionality.

Craig Still

Maintenance Manager, Middletown Industrial, Inc

Some very good nifty features. I have used Maximo and EAM and this definitely holds up. The “work request” feature is amazing, ability to create and edit work requests through email is very helpful.

Farshid R.

Maintenance Supervisor

Why FastMaint CMMS Stands Out from the Competition

- User-Friendly Interface: FastMaint is intuitive to use. A shorter learning curve helps users to quickly become effective.

- Ease of Implementation: Straightforward and quick setup process. This makes it easier and faster to deploy

- Flexible Reporting: Offers flexible and customizable reporting tools unlike many other competitors

- Cost-Effective: A more affordable pricing structure - great for small to mid-sized businesses with budget constraints

- Essential Features: Focuses on delivering a core set of essential maintenance management features without overwhelming users

- Low Maintenance: FastMaint’s simplicity and efficiency often result in lower ongoing maintenance needs, reducing the burden on IT staff

- On-Premise and Desktop Options: FastMaint has both cloud-based and on-premise deployment options. This is crucial for remote or underserved locations

Discover the FastMaint Advantage in Just 2 Minutes!

Was this helpful?

FastMaint CMMS Software Features

For industrial & commercial facilities

FastMaint is a good choice for industrial & commercial facilities of all types such as industrial plants, office buildings, hotels & resorts, power plants, water treatment and more.

Maintenance managers can quickly create breakdown and preventive maintenance plans. Maintenance checklists for equipment & facilities.

Simple to track asset maintenance costs by equipment & facility (location). See how much materials and labor costs. Available as stand alone, networked or cloud editions.

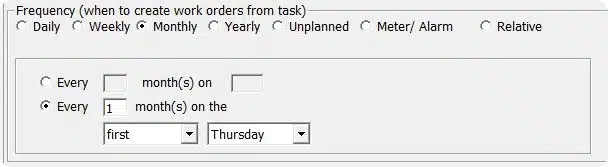

Maintenance scheduling made easy

FastMaint makes it easy to plan and schedule various maintenance tasks through a single interface.

For example, users can schedule unplanned maintenance directly from a task library when equipment malfunctions occur.

Similarly, users can schedule preventive or planned maintenance by creating a library of predefined maintenance tasks.

Users can schedule maintenance work on equipment based on time intervals, such as every four months, or trigger it by changes in meter readings, such as after every 1000 units produced. Also schedule maintenance in response to alarms, completion of other maintenance tasks, and more.

Example: Schedule a monthly maintenance task

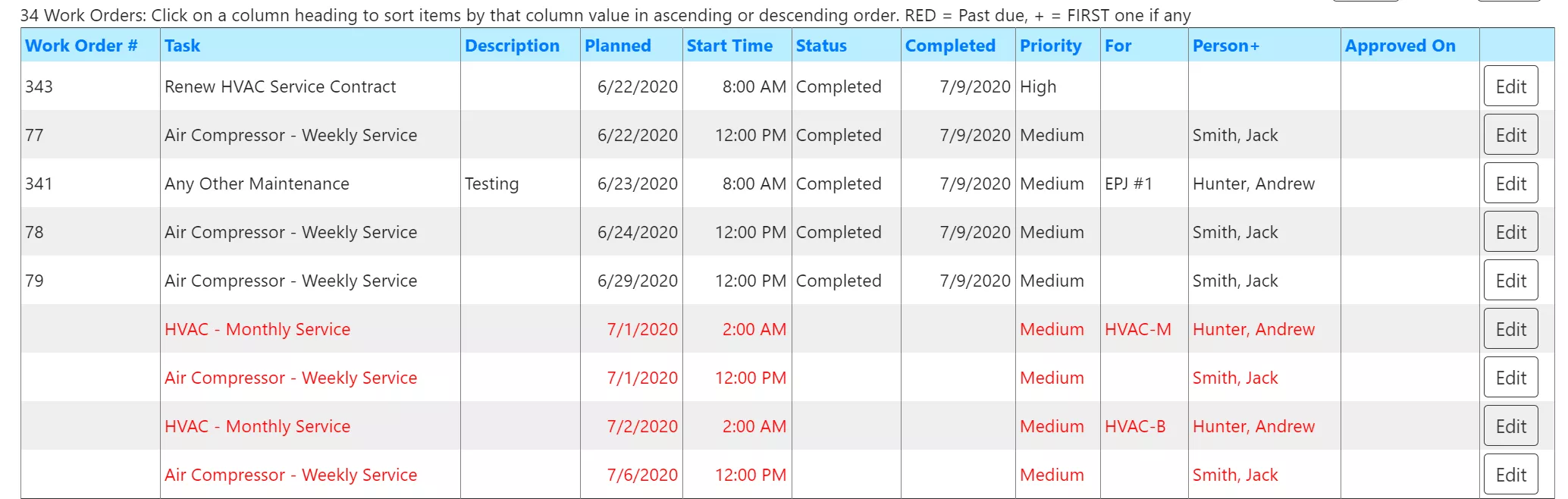

Maintenance work orders don't get lost!

FastMaint generates work orders for maintenance work based on the schedule in the task templates. Maintenance technicians or outside sub-contractors can receive these work orders to complete the jobs. You can print the work orders or email them out and send reminders when they are past due. Furthermore, you can reduce maintenance completion errors by printing pictures and detailed instructions on the work orders.

Maintenance work orders with status

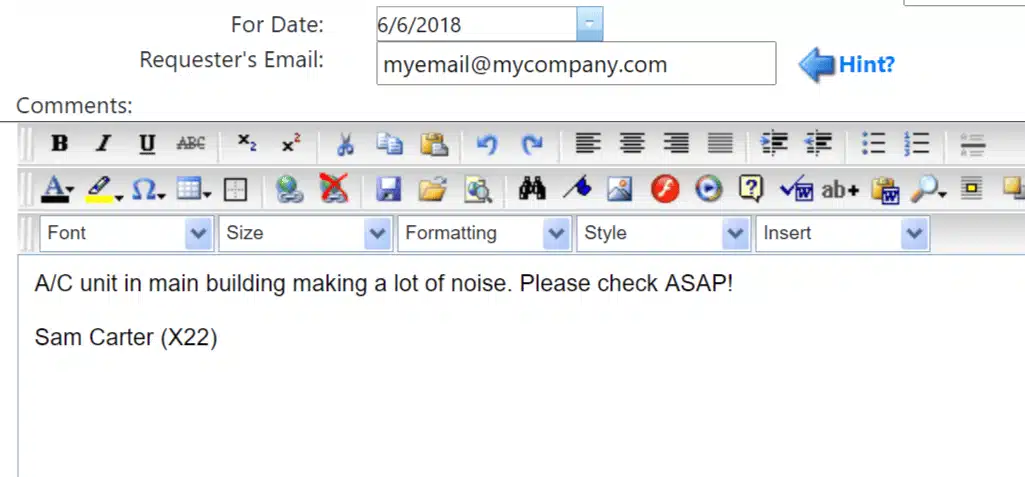

Sample maintenance work request

No forgotten maintenance requests

Machine operators or other departments have the ability to send maintenance work requests to the maintenance scheduler, allowing them to receive and keep track of all requests.

Additionally, they can submit work requests via email, eliminating the need for requesters to set up anything or access FastMaint directly. Furthermore, maintenance requesters can receive updates on the status of their maintenance requests via email, and maintenance schedulers can also email them for additional information.

Maintenance schedulers are able to review these maintenance requests, create work orders from them, or cancel them as needed.

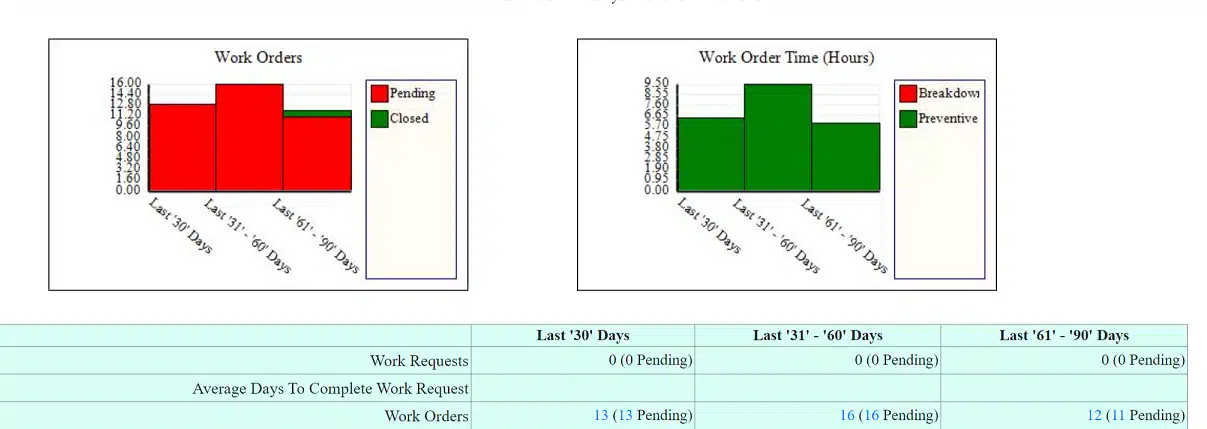

Statistics report showing maintenance performance over time

Continuous improvements with analytics & customizable reports

FastMaint provides numerous reports that you can print or email. These reports offer insights into maintenance work costs, spare parts and supply usage, equipment downtime, and more. For example, the one-page Statistics report provides a quick overview of your current maintenance situation over time.

You can customize most reports to your preferred format. Use the WYSIWYG Report Editor to create your own reports and graphs. For instance, you can add custom fields, company logos, graphs, and other elements to tailor the reports to your needs.

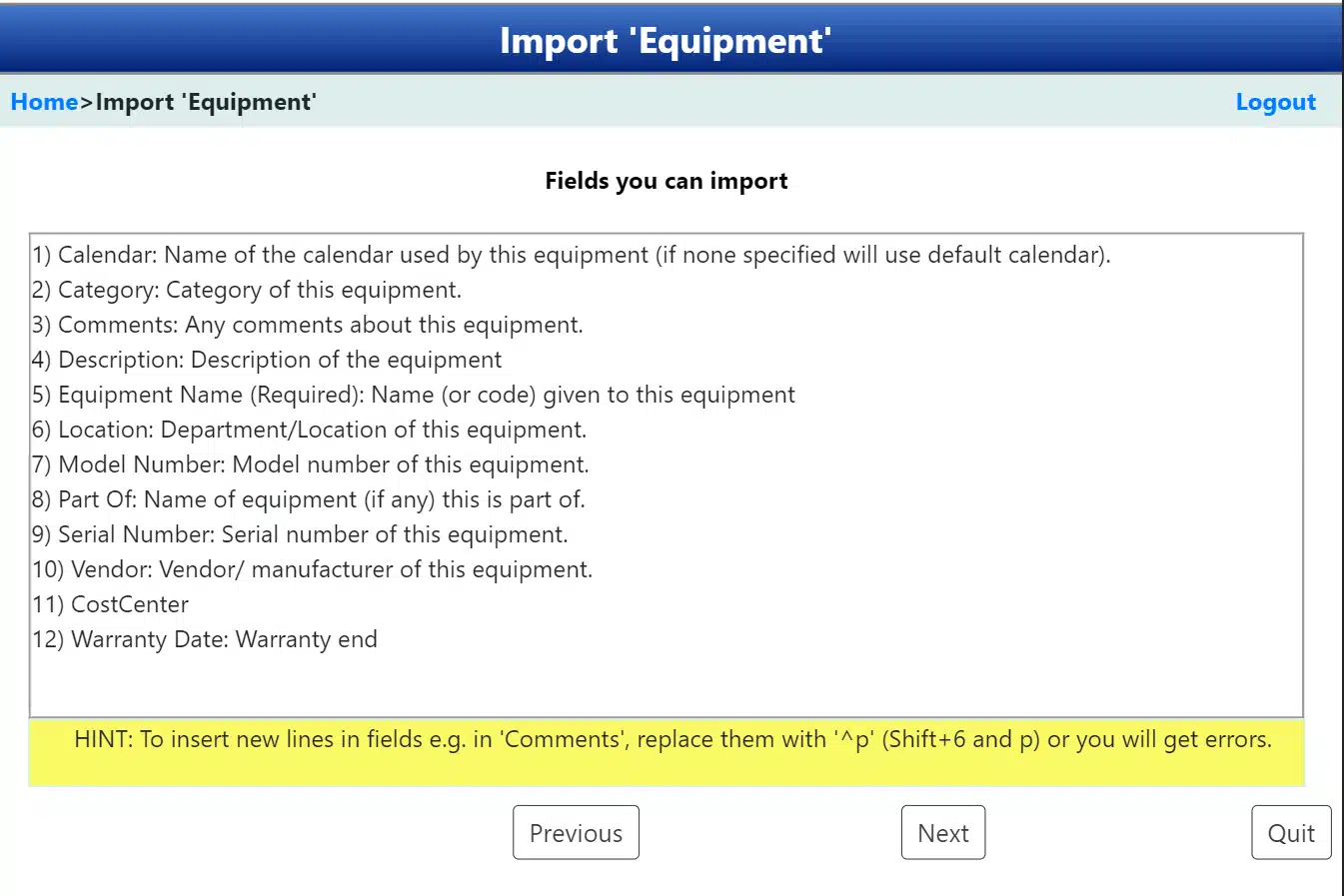

Import your data for a quick start

Do you already have a wealth of data stored in Excel spreadsheets or similar files? You can swiftly import much of this data into the system to speed up setup. Import equipment details, maintenance spares, job instructions, and more, streamlining the process for you to begin.

Utilize the intuitive step-by-step wizard within the Import function to easily map your data to the appropriate fields. Made a mistake? Not a problem! You can rerun the import to incorporate any corrections you’ve made.

Furthermore, you have the capability to export data to Microsoft Excel, such as last quarter’s work orders, allowing for further analysis and insight.

Importing equipment from a Microsoft Excel file