Calculate CMMS Benefits For Your Maintenance Program

“The largest, single controllable expenditure in a plant is maintenance, and in many plants the maintenance budget exceeds annual net profit.”

Reported by E.I. DuPont de Nemours Co. (Delaware), 1996

Experts say that a Computerized Maintenance Management Solution (CMMS) can help organizations save between 5-15% of their maintenance budgets. So even those with maintenance teams as small as one or two people should see many CMMS software benefits. The following example uses FastMaint CMMS for illustrative purposes. Similarly calculate the benefits & ROI in your situation using the CMMS ROI calculator mentioned below. This will help you prepare your justification for purchasing a CMMS system

CMMS Software Benefits Example

ABC Corp. is a small company that manufactures widgets. It has a two person maintenance team. Some of the ways that FastMaint CMMS helps them are:

1. Reductions in equipment breakdowns

Before getting FastMaint, ABC Corp. had a packing machine that needed a weekly safety inspection and monthly bearing replacement. Due to very busy days at the plant, and that one of the maintenance people was out sick, the monthly bearing replacement task was not done. A few weeks later the packing machine broke down unexpectedly due to bearing failure. It took a day to fix.

To meet client deadlines ABC Corp. had to hire four temporary workers for two shifts to pack the widgets. Each worker was paid $8/ hour. This works out to a cost of $512 ($8/hour X 4 workers X 16 hours). Plus there is the cost of any extra work and parts required to fix the broken packing machine. Assuming missed maintenance causes two events like this every year, it will cost ABC Corp. about $1024/year or more due to equipment breakdowns that could have been avoided.

With FastMaint CMMS it is easy to schedule the task at a better time. When creating the weekly/ daily plan or reviewing the workload for a period, it is easy to see that there is a conflict since someone needed for the task is going to be out. Even if it is not caught at the planning stage, it will be identified as as a pending task once it is missed.

2. Reductions in overtime costs

Due to difficulties in scheduling maintenance just using pencil and paper or spreadsheets, the two maintenance people at ABC Corp. averaged six hours of overtime a week.

With FastMaint CMMS, ABC Corp. can better schedule maintenance work and finds that it reduces overtime by a third.

Assuming both maintenance people need to be paid overtime and their rate is $10/hour ($15/hour overtime rate) this translates to a yearly savings of $1040 ($5/hour extra for overtime X 2 people X 2 hours saved/ week X 52 weeks).

3. Longer asset/ machine life

ABC Corp. owns two trucks that need regular maintenance. These maintenance tasks were missed sometimes and result in the trucks requiring to be replaced earlier than expected due to premature failures.

Each truck costs $50,000 to replace and has a usable life of ten years. Assume that missed maintenance reduces the truck’s usable life to nine years (10% reduction in lifespan).

This results in an additional capital cost of $10,000 (assuming $5,000 depreciation on each truck per year). This is an extra cost of $1,000 per year over the life of the trucks. With FastMaint CMMS it is easier to schedule & track the maintenance needs of the trucks – potentially increasing their usable life.

4. Better inventory management

ABC Corp. spends about $50,000 a year on parts required for equipment maintenance needs. With FastMaint CMMS they can better track inventory, when to restock items and quickly identify parts that are no longer required (because the equipment is retired). ABC Corp. finds out how many parts of each type they need for preventive maintenance tasks for each quarter by using the Planning Report to calculate parts and quantities needed. This helps them apply for volume discounts as they know how many they will need in advance.

They also keep less inventory on hand because FastMaint CMMS warns them when each different part falls below reorder levels.

Experts say that organizations can save between 5-10% on their yearly inventory costs with a CMMS. This translates to a savings of at least $2,500 a year for ABC Corp.

5. Other CMMS benefits

ABC Corp. finds that using FastMaint CMMS gives them improved control over their preventive maintenance schedule. They have better statistics on their maintenance needs as well as information on failure trends.

For example ABC Corp. analyzed the Task History reports produced by FastMaint CMMS and found that whenever Tom did maintenance on a machine it seemed to break down more frequently compared to when Jack did the work. Checking with both of them they found that Tom did not realize that a washer needed to be replaced when maintenance was done.

FastMaint CMMS can help establish and record best practices in the several pages of Instructions that can be entered for each task and printed on the work order for the task.

ABC Corp. also find the maintenance reports that FastMaint CMMS creates are useful to get certification and comply with local health and safety standards. Not performing certain mandatory maintenance safety checks & tasks on time can result in big fines from local authorities.

Calculating The Payback Period

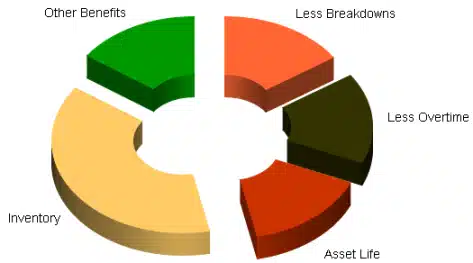

| Less Breakdowns: Yearly savings due to reductions in equipment breakdowns | $1024 |

| Less Overtime: Yearly savings due to reductions in overtime paid | $1040 |

| Asset Life: Yearly savings due to increased asset life | $1000 |

| Inventory: Yearly savings due to reduced inventory costs | $2500 |

| Other Benefits: Improved maintenance practices, Certification benefits, Reductions in fines/ forced shutdowns, etc… | Variable |

| Total potential yearly savings for ABC Corp. | $5564+ |

We can see that ABC Corp. get several benefits from using a maintenance software package like FastMaint CMMS. The potential yearly savings add up to over $5,500 a year plus the other benefits mentioned.

Assuming ABC Corp. bought a copy of FastMaint Standard (single user) this is a payback period of less than five months. If they bought FastMaint Professional (five user) this is a payback period of less than eleven months. This falls well within recommended guidelines of payback in a year or less for most projects.

Calculate Your Own CMMS ROI

Want to estimate your own potential savings with a maintenance software program? You can use our quick and easy to use “CMMS ROI Calculator“. It will give you an estimate of your savings which coupled with your CMMS software costs will help you build a return on investment (ROI) case.

We hope this convinces you that a maintenance software package like FastMaint CMMS is well worth the price. We welcome your feedback and comments.

Have questions? Contact Us