Maintenance Management Software - FastMaint CMMS

Reduce downtime. Increase productivity. Simplify asset management. Optimize preventive maintenance.

No credit card required

Used by

Streamline Maintenance and Asset Management With FastMaint CMMS

- Manage unplanned (breakdown) & planned (preventive) maintenance jobs

- Work order templates integrate best practices & improve compliance

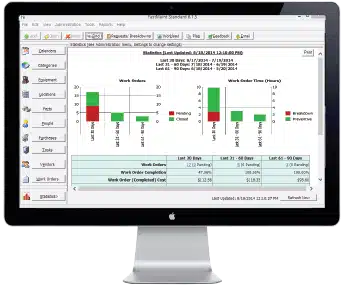

- User-friendly dashboard helps improve maintenance efficiency

- Identify missed maintenance. Reduce breakdown/ emergency maintenance

- Work order management, inventory management, track maintenance costs

- Available for a One-time fee (downloaded software) or monthly subscription (Cloud CMMS)

- Download & use the trial. Keep your data when you convert it to the full version

(Download or Cloud CMMS)

CMMS solution that helps even maintenance teams as small as one or two people improve asset reliability & asset performance.

Try On-Premises Or Cloud CMMS Software

Compare editions & features

For Windows 10, 11

In your web browser

FastMaint CMMS Maintenance Management Program Editions

Standard edition: A single user version suitable if you need to do maintenance of equipment or facilities

Professional edition: A multi-user version that can handle your maintenance of a large number of equipment or facilities. Works with a built in Microsoft Access database (no license needed) or an external Microsoft SQL Server database.

Web edition: A multi-user version that can handle your maintenance needs for a large number of equipment or facilities. Works with a built in Microsoft Access database (no license needed) or an external Microsoft SQL Server database. Use it with a web browser on desktops, laptops, most tablets & smart phones.

Cloud edition: A multi-user version very similar to the Web edition. It is hosted on our servers and has an affordable monthly subscription. Use it with a web browser on desktops, laptops, most tablets & smart phones (mobile app style).

Manage Maintenance Requests & Work Order Workflow For

Maintenance Management Software Tips

From Our Blog

Maintenance management covers a wide area since regular maintenance is required for a variety of assets. Computerized maintenance management software is not only useful in locations with a lot of machines (e.g. manufacturing plants, mining operations, etc.) but useful where you have a lot of facilities needing maintenance (hotel, resorts, restaurants) as well as those with other equipment (e.g. utilities, vehicle fleets).

read more

Some maintenance jobs can be costing more than you thought! Maintenance and operations managers usually look at maintenance data by equipment to identify equipment that is getting expensive to maintain. However, there are other ways to to slice your data and look for ways to reduce costs and improve effectiveness. For example consider the costs of different maintenance tasks or jobs. This is especially relevant when you may have lots of very similar equipment. You may have several pumps of the same model, several similar HVAC units and so on.

read more

Maintenance backlog refers to maintenance work that is overdue.It is a very important maintenance metric for facilities managers, maintenance managers and maintenance planners. Big increases in maintenance backlog should be taken seriously! What causes maintenance backlog?

read more